Coimbatore, India

Call us now

08041091780Industrial Ovens

About this product

Product Details:

| Minimum Order Quantity | 1 Piece |

| Capacity | 100 Kg |

| Brand | MV International |

| Oven Type | Cabinet Ovens |

| Temperature | 300-400 deg. Celsius |

| Display | Digital |

| Air-Flow Direction | Vertical Down Airflow |

| Automation Grade | Automatic |

| Display Type | Digital |

| Door Type | Double Door |

| Size | 24 x 24 x 24 Inch |

| Voltage | 415 V |

| Warranty | 1 Year |

| Heating Load | 9.75 KW |

| Frequency | 50 Hz |

| No. Of Trays | 5 |

| Blower Load | 1 HP |

| Inner Chamber | MS or SS 304 |

| Material | Stainless Steel |

Manufacturing Industrial Ovens as per client requirement.

Features:

- Digitally Controlled

- Custom Shelfs

- Temperature Recorder

- Electric, Gas-Fired, Diesel etc.

- Tray and Trolley available

Coconut fiber dryer

325000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 1 Week

Voltage 220-440 Volt (v)

Usage Coconut Fiber Machine

Product Type Coconut Fiber Machine

Condition New

Application Industrial

Supply Ability 10 Per Month

Payment Terms Cash Advance (CA)

Main Export Market(s) Asia

Main Domestic Market All India

About this product

Sand Dryer

Minimum Order Quantity : 1 Pieces

Delivery Time : 1 Week

Voltage 440 Volt (v)

Product Type Sand Dryer

Condition New

Color Gray

Capacity 2000 Kg/hr

Application Industrial

Supply Ability 10 Per Month

About this product

Product Price: Rs 8.25 Lakh / Piece

Product Details:

| Capacity | 2 TPH |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Max Temperature | 600 degree C |

| Voltage | 440 V |

| Usage/Application | Industrial |

| Frequency | 50 Hz |

| Country of Origin | Made in India |

Fish Dryer Machine

Minimum Order Quantity : 1 Pieces

Delivery Time : 1 Days

Weight 650 Kilograms (kg)

Voltage 220 Volt (v)

Product Type Fish Dryer Machine

Power 0.3 Watt (w)

Condition New

Color White

Application Industrial

Supply Ability 10 Per Month

About this product

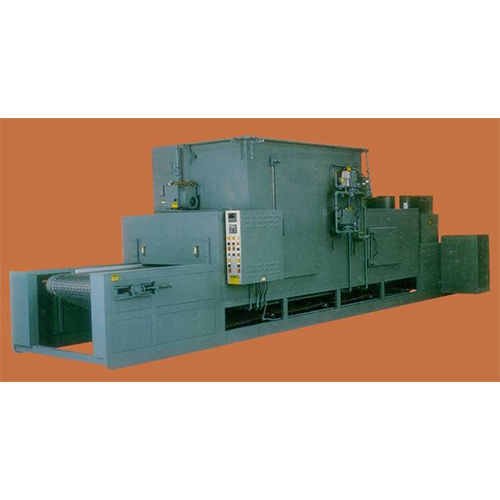

On Line Conveyor Ovens

Minimum Order Quantity : 1 Pieces

Delivery Time : 1 Week

Voltage 220-440 Volt (v)

Type On Line Conveyor Ovens

Product Type Conveyor Ovens

Condition New

Color Gray

Application Industrial

Supply Ability 10 Per Month

About this product

- Labour is reduced as the material is loaded directly on conveyor.

- Continues production is possible.

Conveyor Ovens

About this product

Operation

Conveyor drying uses a perforated belt to transfer feed materials through the dryer. Heated air is either passed under and through, or over and through the belt and product bed before being reheated and re-circulated. Units are normally multi zoned and may have differing airflows in successive zones. Additionally each zone may use a different temperature profile and control. Saturated or close to saturated air is exhausted from the dryer via a central exhaust duct.

Conveyor dryers may be multi pass units, in which the feed is transferred from one belt to another belt below it by gravity. These dryers are usually two or three pass machines. Additionally certain conveyor dryers, such as those used in vegetable dehydration have multiple belts in line, and the feed is transferred from one belt to another.

SAKAVs experience in the design and manufacture of conveyor ovens has resulted in a wide range of units. Electric gas and steam heated units with operating temperatures from 650C to 6500C, have been created for all fields of industry.

Each unit is specifically designed for the customers process and can include:

- Multiple heat zones

- Extended loading and unloading zones

- Special belt construction or attachments

- Cooling zone to reduce part temperature

- Aluminized or stainless steel interior depending on maximum temperature rating.

- 16 gauge aluminized steel exterior with enamel finish

- Welded structural steel, channel base provides a rigid assembly easily moved at any time.

- Heavy duty, all welded, structural steel slide bed is supported by cross angles welded to vertical structural members to transfer load to base

- Belt slide bed herringbone construction provides for even belt wear.

- Side hinged doors provided along oven length for access to work space and heat chamber.

- Heavy duty variable speed belt drive with torque limiting device

- Belt tracked and guided as necessary with rollers to prevent wandering and potential belt damage

- Adjustable dampers at each end of heat zone can be positioned near load to minimize heat loss from end of oven.

- Adjustable patented opposed louvers on full coverage supply and return ductwork.

- Duct work removable for cleaning

- Brushed stainless steel control panel face

- 1 year limited warranty

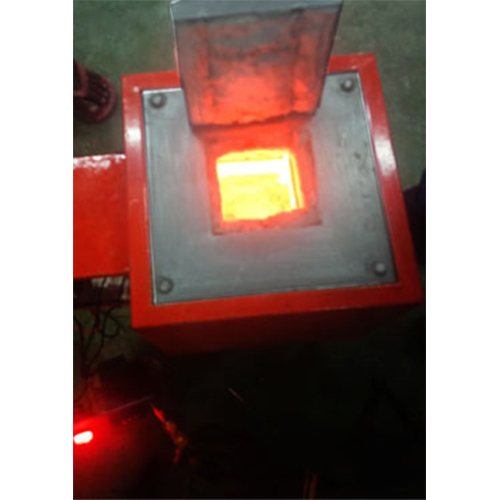

Non-ferrous Furnace

About this product

Designed for LPG firing, we offer premium Bogie Hearth furnaces. Here by implementing gas firing we insulate the furnace using ceramic fiber module lining. These furnaces have walls, roof and also have movable bogie hearth. Here Bogie can be placed on wheels to move manually or mechanically using winch mechanism. In this system the door sealing is provided by butting door lining and collar lining. In addition to this hearth brick to brick sealing is provided by stepped lining and bogie have stand sealing arrangements all over bogie sides except front or side. These Bogie Hearth furnaces (gas fired type) are also provided with single burner up to 2 tonnes batch capacity.

Rotary Furnace

About this product

We are engaged in supplying industrial furnaces and industrial oven as per customers specifications with superb design and excellent quality. These are offered in process specific finishes. Further, our industry expertise also allows us to deliver these in finish specifications as demanded by the customers.

Rotary Furnace

Rotary furnace is mainly used for melting.

- Lead

- Aluminum melting

- Copper melting etc.

Rotary furnace is gas fired, diesel fired of furnace oil fired. The rotary furnace is rotated or tilted. One end burner will be fitted and other end will be having movable exhaust duct to load material . The exhaust duct will be having cyclone seperator, wet scrubber or dry scrubber, bag house etc.

Crucible Furnace

About this product

We at Pyrotech Engineers, are proud to state that we are one of the few names to offer premium Crucible Melting Furnaces that are easy to install and require less maintenance.

Manufactured as:

- Melting furnaces

- Melting cum holding furnaces

- Holding furnaces (only for Aluminum) are mainly used in gravity die casting

- Sand casting

- Pressure die casting units

Core Oven

About this product

Product Details:

| Minimum Order Quantity | 01 Unit |

| Capacity | 100-500 Kg |

| Max Temperature | 1200 Degree C |

| Material | Mild Steel |

| Air-Flow Direction | Vertical Down Airflow |

| Display | Digital |

| Automation Grade | Semi-Automatic |

Features:

- Impeccable performance

- Longer working life

- Energy efficient

- Simple to operate

Core Oven

About this product

Product Details:

| Power Source | Electric |

| Usage/Application | Industrial |

| Oven Type | Cabinet Ovens |

| Temperature | 100-200 deg. Celsius |

| Material | Mild Steel |

Specifications:

- High strength

- Smooth Work

- Error Free

Features:

- Non-corrosive

- Easy to use

- Perfect design

- High durability

- Sturdy construction

Tilting Furnace

About this product

We also offer premium Bulk Melting/Tilting Furnaces that are mainly used for random melting of runner, raiser and ingot. These furnaces are also used for the preparation of molten metal. In addition to this it is to be noted that after melting the molten aluminum, it is treated for de slaging and de gassing. These furnaces are indirectly fired by gas or liquid fuel and metal is tapped by tilting the furnace. The tilting is done by manually or with the help of hydraulic cylinders.

- Manual tilting furnace: Here the tilting furnace is held on two shafts mounted on bearing blocks and this shaft is actuated manually by work and worm gear with steering type handler.

- Hydraulic tilting mechanism: Here the furnace is held as explained in manual tilting mechanism and a hydraulic cylinder is used for tilting the furnace along with the hydraulic power pack.

Explore Additional Categories

Contact Us

Our Products

Our Products